Projected Capacitive Touch Panel

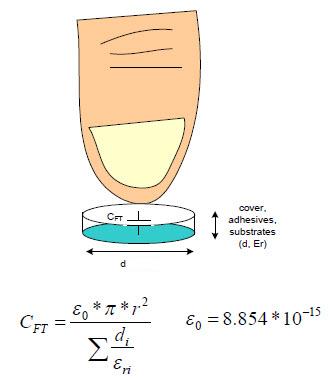

The Projected capacitive touch screens use a glass substrate with a tin oxide coating that is charged with a slight electrical current. When a conductive stylus or finger touches the surface, it creates a capacitive coupling that causes a current draw at that point. The x- and y-coordinates can then be determined. The capacitance is calculated as below,

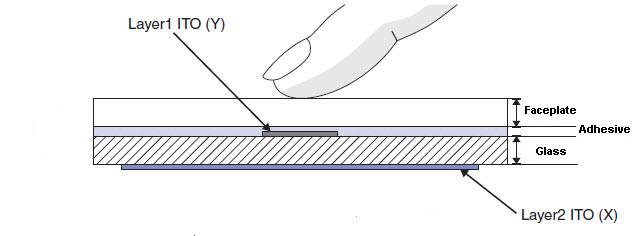

The glass substrate of a capacitive touch screen is resistant to scratching, capacitive touch panels are with benefits of better durability and higher optical clarity(The below shows the typical stack of projected capacitive touch screen), and the touch-screen system can be built to NEMA 4/4X standards. Besides these physical advantages, capacitive touch panels scale new heights in realizing multi-touch application, which has changed the perception of the touch panel interface. With such distinctive features, the capacitive touch panel become a mainstream touch technology and bring the market lots of innovative touch interface designs.

Projected Capacitive Touch Panel Advantage:

. High durability, suitable for outdoor application and insensitive to scratches, dirt etc.

. High optical transmission

. Extreme long life time

. Fast response time.

. High resolution.

. Decorating faceplate can be added on the top of touch panel.

. Both bare and gloved finger can still work.

. Better ESD performance.

. Good track for both single-touch and multi-touch action.

. Easier to do refraction index matching in structure wise.

.

The drawback of this technology:

. Certain size of conductive pointing object required.

. Low noise Immunity.

. Faultless with particular size of water droplet.

. Relatively higher cost.

Even with these drawbacks, with picking up proper touch panel controller and optimizing the touch panel pattern and structure design, these drawbacks can be improved or even be eliminated completely.